Productive process

Basalt stones are smelted by high temperature and then become magma. Pour the magma into rotary furnace. In rotary furnace, the magma takes initial impurities precipitation and gas floatation. Then, they enter into a big casting ladle. The magma takes initial impurities precipitation and gas floatation again in the ladle. After that, they are poured into moulds which have been preheated. The magma take shapes quickly in the moulds. For removing the products` internal stress, they are put into tunnel annealing kilns. After 24hours, they are out of the kilns and put outside.

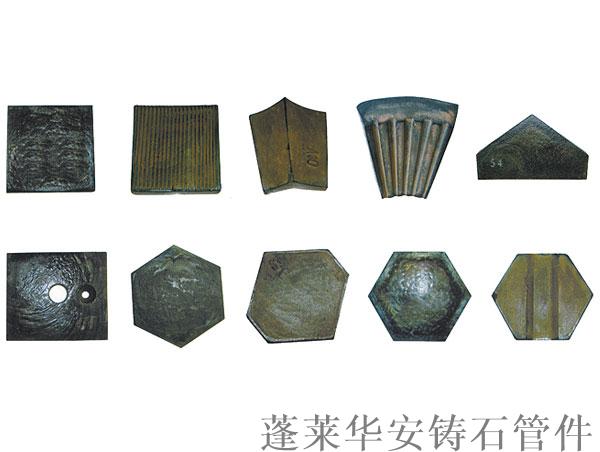

1/ Tiles

cast basalt tiles may be used in all kinds of ways.Such as : the liner of coal bunker of power station,the lining of dust cyclone and classifying cyclone,the liner of chemical storage tank and warehouse for corrosion material,the floor material for chemical plants and lowfriction vehicle testing surface etc.

We can offer any shape,size and thickness tiles to meet your need.

2/ basalt liners

The composed basalt liner has been widely used in power plant for ash/slag disposal chute.We can offer various size and series of basalt liner including:straight through ,radial shaped,bend through,Y and T through according to the order.

In short,cast basalt tiles can be mainly used as various chute slip trough,funnnel,silos,a variety dust catcher ,revolving-flow machine,various scraper transport planes,all the feeder liner.Laying the ground all types of chemical plants.It can be used for automobile brake testing ground floor,and so on.It also can be for lining picking tank or storage of corrosive substance of the storage room.

According to customer requirements along with cast basalt production technology and we can offer various specifications and various shape to meet customers' requirements.

cast basalt products - physical and chemical performance

Category | Attribute |

Specific Gravity | 3g/cm3 |

Compressive Strength | 686 MPa or higher |

Bending Strength | 60 MPa or higher |

Impact Strength | 1.76KJ/M2 |

Abrasion Strength | 0.07g/cm3 |

Vickers Scale | 720kg/ or higher |

Thermal Expansion Coefficients | 60 max 8.92*10 -6 |

Elasticity Modulus | 1.67*105MPa |

Chemical Attack Resistance | |

95%-98%H2SO4 | 98% or higher |

20% H2SO4 | 94% or higher |

20%NaOH | 98% or higher |